The 280g reef is leaking

by

, 07-03-2010 at 04:53 PM (29463 Views)

The top left corner of my tank is leaking. Ugh. I'm going to have to figure out what I can do about it today. The carpet is wet in the entry way.

Update 7:57 pm 7/03/10:

Here are the pictures I took this afternoon. I didn't take a picture of wet carpet because you know what that looks and smells like. I removed the wooden column on the left side of my tank as soon as I saw how it was soaked with saltwater. I also checked tank salinity, and it has dropped to 1.024sg. I'm making RO/DI water now, and will probably keep it going all night.

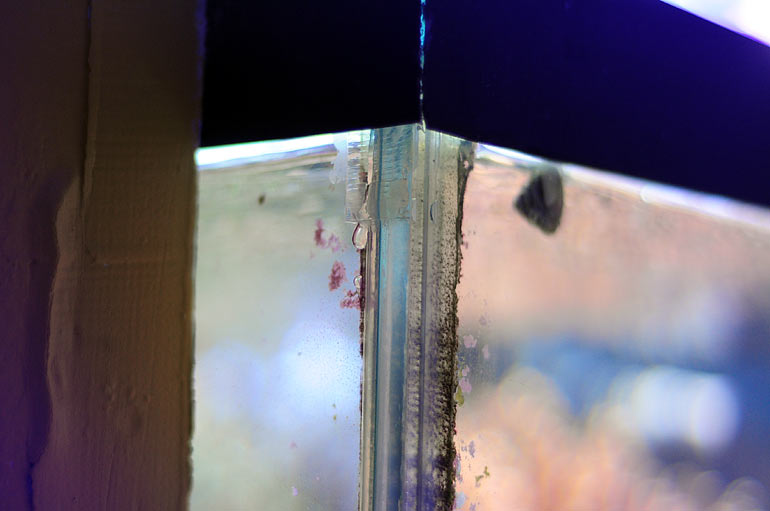

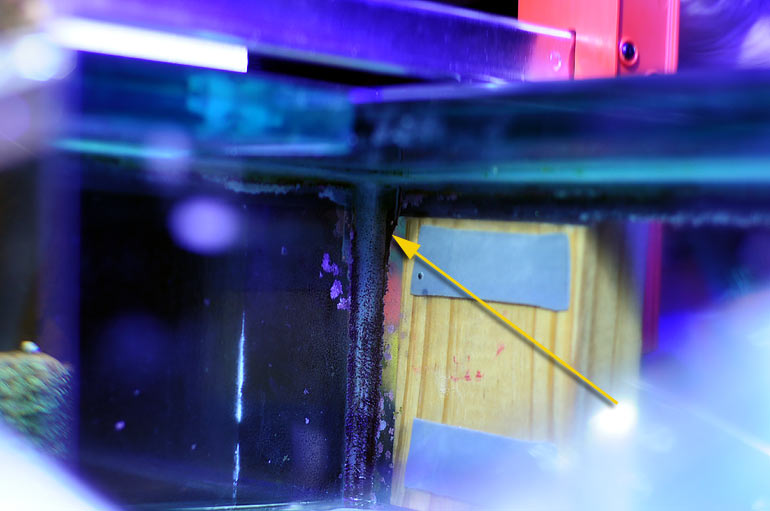

Here's the leak. Doesn't look like much until you realize it drips non-stop.

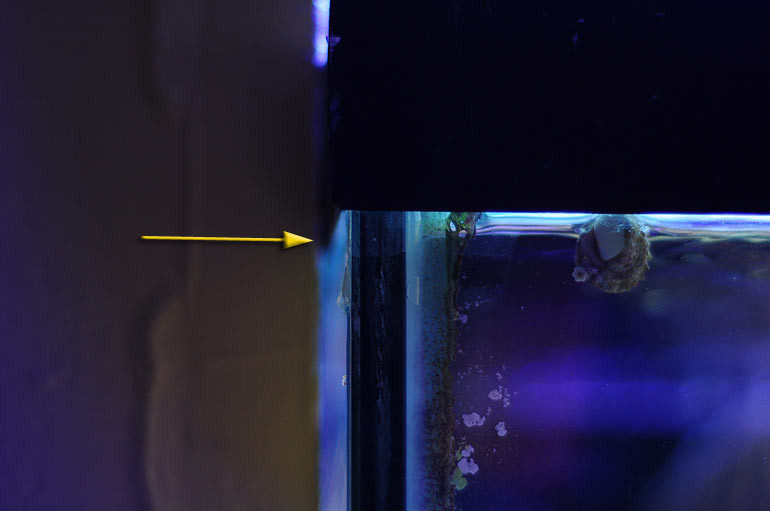

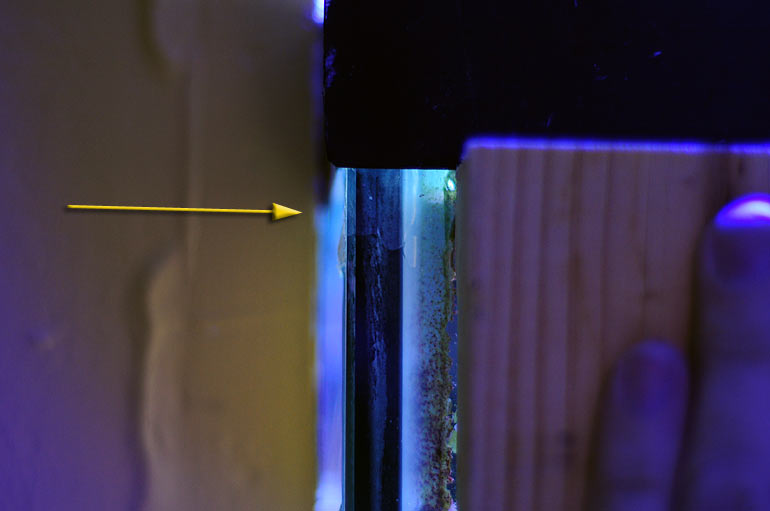

Note the hollow spot pointed out where the silicone is no longer making contact, below the water line.

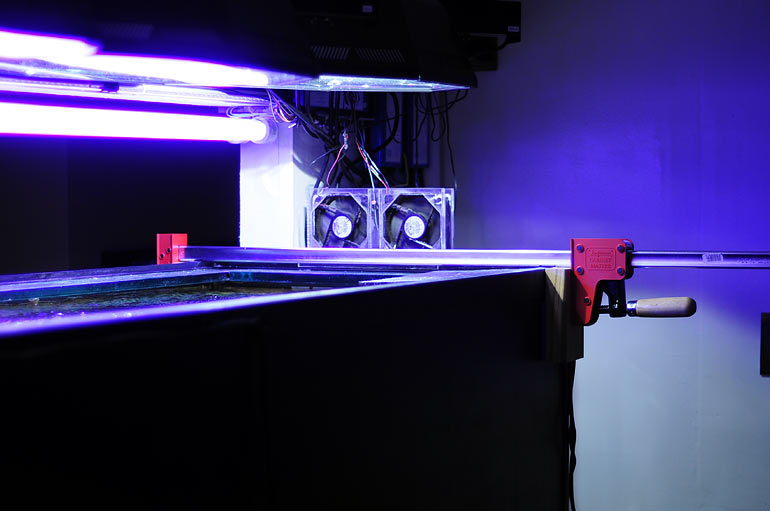

At Home Depot, I found these huge 48" clamps for $40 each. I bought two, but only have one in place at the moment.

A wooden block front and back helped disperse the pressure a bit. I had to improvise because of the plastic trim. For the back piece, I used a piece of acrylic behind the block to help even out the pressure.

For the front, I ran a block through my table saw to create a small offset.

As soon as it was clamped, I slowed the leak down. A couple of ml have drained so far.

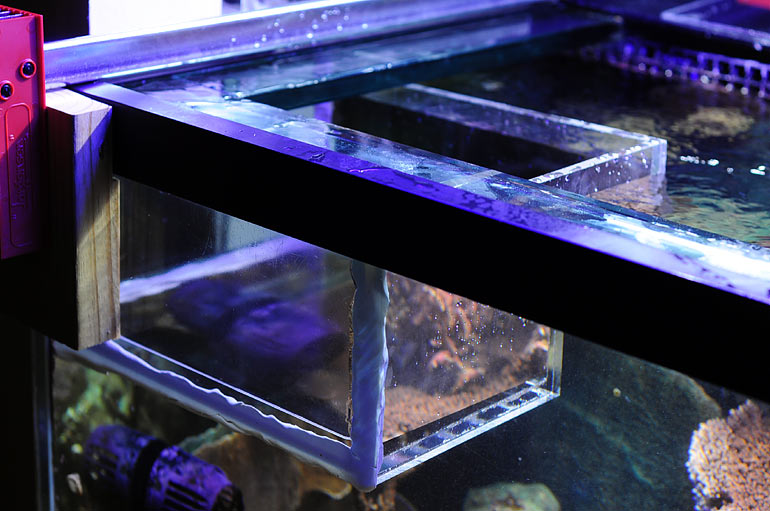

While that was holding, I grabbed some 3/8" acrylic and created a internal overflow, so to speak. Using common Plumber's Putty, I rolled it out 1/4" thick and created strips to affix to the edges that would press against the glass. Not may favorite choice, but I had to do something. My skimmer hasn't gone nuts yet.

The water pressure holds the box in place, once I scooped & siphoned out the water in the box to create that dry void.

Had to rescue this lost snail.

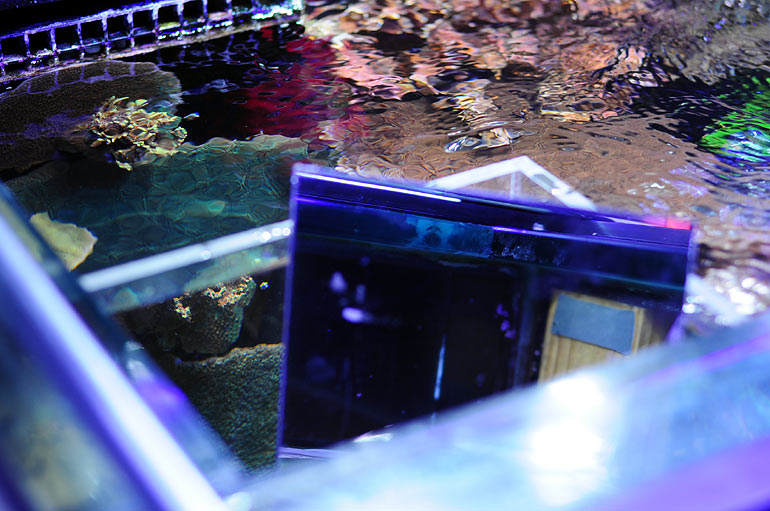

I had some acrylic mirror material to see what is going on in the corner now that the water was out of my way.

For now, I'm planning to cut out the current silicone in that corner and reapply new silicone to the area. It's a patch, and essentially hold things together and keep the water in my tank for the time being. I hope the putty doesn't hurt the livestock (it isn't melting), and the box doesn't drop away all of a sudden.

UPDATE 12:39 am 7/04/10:

The mending job is not going to help save the tank. The seam continues to fail, which was visibly altering as I worked the silicone in the dry box above. It was frightening, actually. I drilled a hole through the wall for a second clamp to be implemented.

The towels did a good job sopping up the water from the leak earlier today, but I'm not doing anything else with the chance that it is going to blow out soon.