Tank Stand

by

, 05-04-2011 at 02:40 PM (1465 Views)

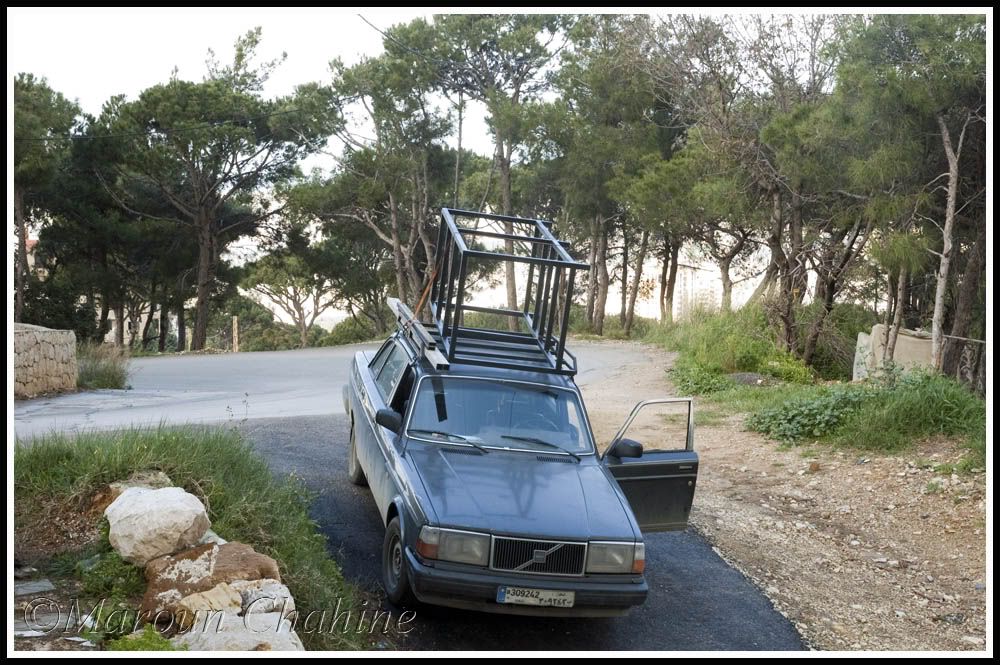

Stand was delivered.

4x4 cm 3mm think steel (1.6x1.6 inch 1/8" steel bars)

Was 2.5 inches taller than ordered so had to cut down a bit from the legs, hopefully that won't make it very hard to clean under it.

Also wasn't impressed by the epoxy paint they did so had it resanded and repainted on site by 3 coats of epoxy. which took a few days to get done.

No positioning conflicts between in wall setup and stand excpet that the added length would have placed the tank top too close to the vents so I decided to have it cut ddown to the requested height 36 inch (90cm)

Have used Leveling feet on my 150 G tank however with the added weight of this tank I was afraid it would fail or that the screw threads would break so will be shimming the tank.

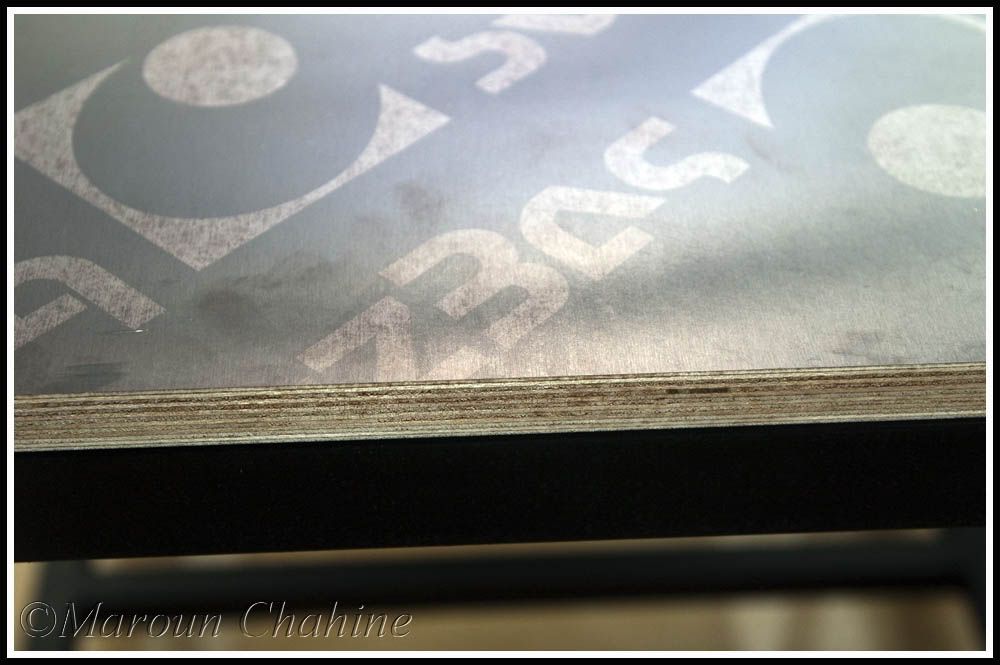

Will use this Russian Marine plywood under the tank:

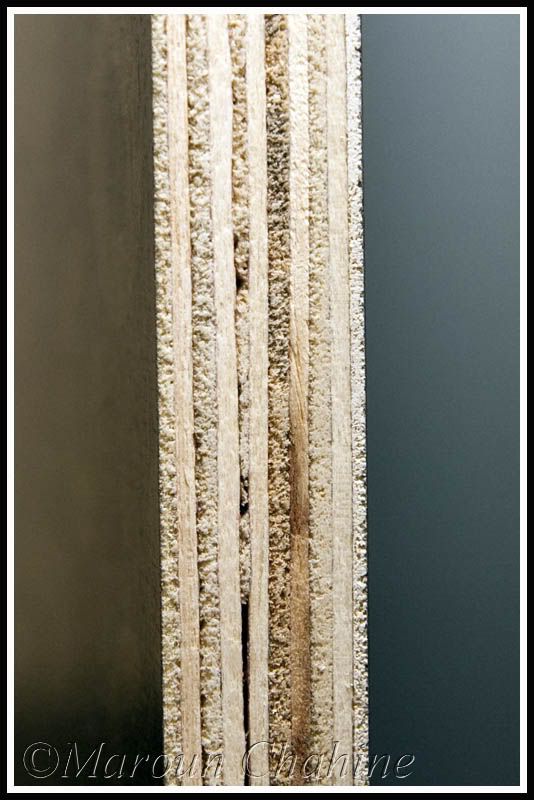

and this one under the sump

They both have the unsealed sides where they were cut. Is there any need to seal those and what would you use:

I'm planning to use some type of aluminum fiber and a thick rubber on top of it belwo the feet. The aluminum fiber is very thin and I can add more or less to level the tand and the rubber will serve to equalize pressure under the feet which are covered by a steel sheet.

Any comment or recommendations on other material to be used?