Plumbing: Return assembly with Penductors

by

, 01-29-2011 at 03:55 AM (14008 Views)

With all the months of planning, I still found myself thinking about how I wanted the plumbing to be, pondering on what would be the ideal layout that wouldn't result in having to make changes and modifications later. I had some crazy ideas in mind originally, but modified them some.

The principle is simple: Water drains into the sump. Water goes back up to the display tank. Avoid too many turns and fittings, and keep it looking clean.

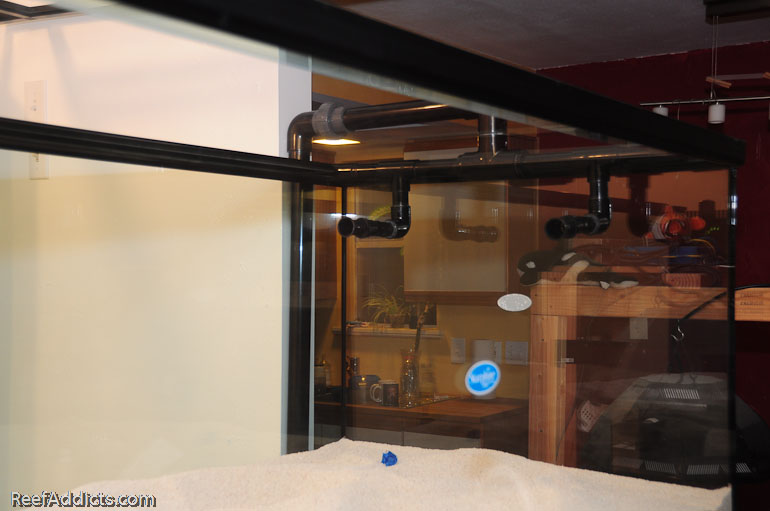

The return assembly was a big deal all by itself. Pete gave me a great idea of how to secure it between the eurobracing of the tank, and I just had to come up with a working creation. Putting the Sequence Dart pump underneath the area where the twin returns would be, it limited the total plumbing significantly. For this tank, I'm using Penductors (flow accelerators).

First I laid out the pieces to visually see what it was supposed to look like.

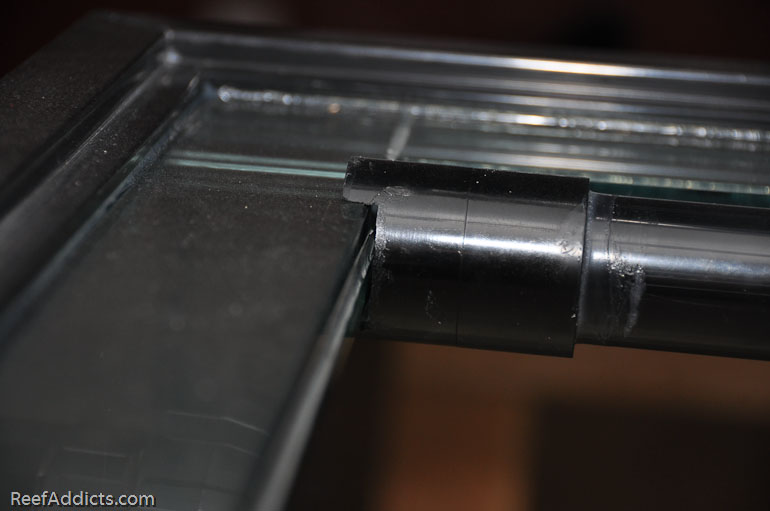

The end pieces that would press against the eurobracing had to be notched, and water couldn't come out of those ends of course. Pete had seen some reverse plugs that he felt were perfect for the job, but I couldn't use those since my parts were slip fittings. I found alternatives, but it involved a Dremel with a sanding bit to create the piece I needed.

I needed that white fitting to slide into the black coupling. The thicker rim needed to be sanded away to all the fitting to seat within.

The plumbing from the Dart pump is 1.5" in diameter. Running 1.5" to the center of the return assembly, it had to then reduce to 1" PVC. The adaptors didn't come in black, so I had to paint the area that would be visible, but not paint where it would be glued. Masking off those areas was key. The fittings were painted, allowed to dry overnight and were ready the next day.

Here it is, just about ready to glue.

The Dremel'ed fittings were glued into the couplings, and painted at the same time.

Notching them for the 1" eurobracing wasn't fun and took some time. I don't have any pictures of that since I was busy watching that I didn't lop off any of my fingers running the end piece across the table saw about 10 to 15 times to create the perfect gap or notch. It was then painted again where the white was revealed.

To assure that no water would weep out of this part of the assembly, I filled it with silicone prior to gluing it.

Now it is taking shape, giving you a much better idea of what I'm building. You can see small sections of 1" pipe that was cut to glue between each of the Tee fittings.

The penductors have to be submerged about 2.5" beneath the water's surface to avoid sucking in air.

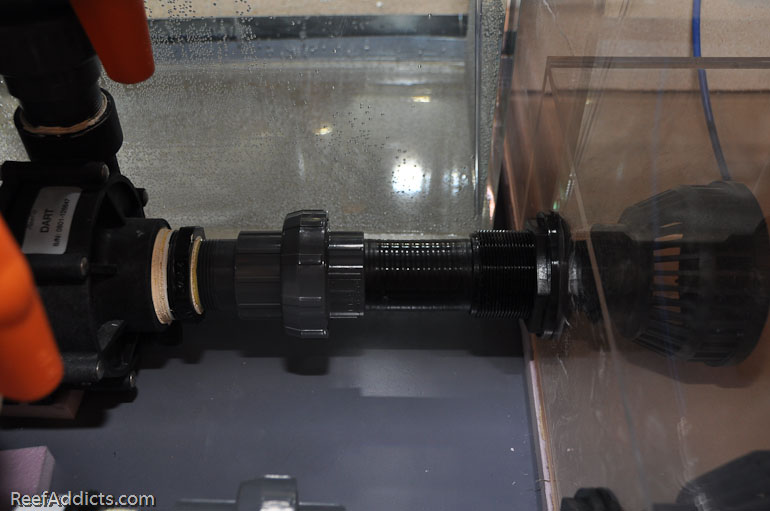

I used a union in case I have to remove the assembly in the future.

With the assembly done, let's focus on the plumbing going into and out of the Dart pump. This can be challenging. The Dart's intake is 2" in diameter, and it is a threaded opening. The output side is 1.5", threaded. I called up their toll free number to discuss the two sizes to find out if there was a reason why it was 2" going in. I was told that as long as the "in" is the same as the "out", there's no problem and cavitation won't occur.

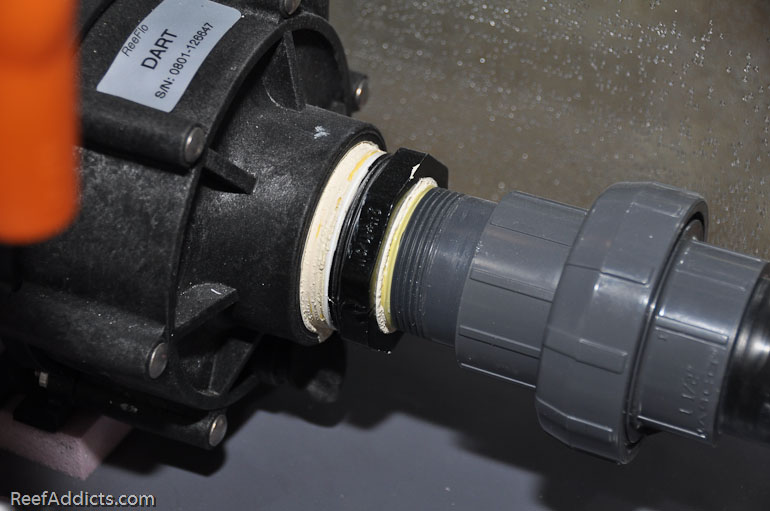

I painted a 2" to 1.5" adaptor to screw into the intake side.

Two 1.5" (6" long) nipples were purchase from Savko.com for the express purpose of plumbing in two Dart pumps. By cutting the nipple in half, you end up having a threaded/slip fitting for both sides of the pump.

The threaded side screws into the pump, and the slip fitting glues into the union / double-union ball valve.

All threaded sections were wrapped with teflon tape and then a layer of teflon paste, and the slip fittings were primed and glued.

With this section fully assembled, it was ready to be installed by the sump.

A 6" piece of black 1.5" SpaFlex was glued between the bulkhead and the union. Please note: When gluing SpaFlex, it takes longer for this to cure. After the tubing was glued into the bulkhead and the opposite end in the union section, it was left to cure overnight before I connected it to the pump. If this process is rushed, the tubing can pull lose from the fitting instead of getting a solid purchase on the PVC. Avoid applying pressure to these areas; give them time to cure before proceeding.

The union allows me to remove the pump for servicing or to change it out for another one.

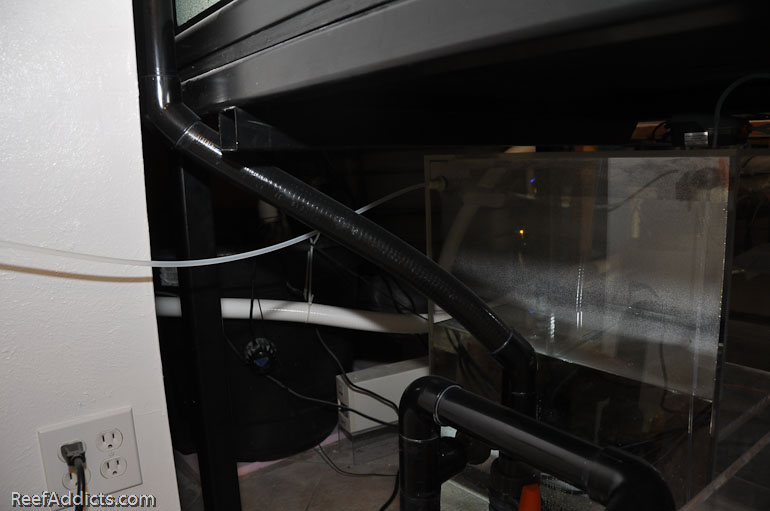

On top of the DUBV (double union ball valve), a Tee fitting and a 45 degree fitting points upward. Black SpaFlex tubing then runs upwards to the next section of plumbing. It was my best option. It is a little forgiving if the fittings aren't lined up perfectly, and removes vibration issues from the pump & plumbing. Ignore that orange handled valve to the left in the next image, as that will be explained later.

Using another 45 degree fitting, the plumbing now points upwards.

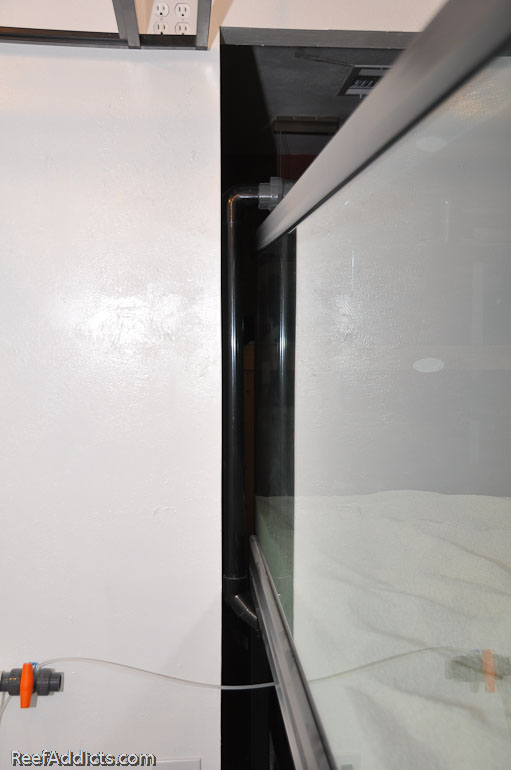

This section of return plumbing uses rigid 1.5" black PVC to hug the wall adjacent to the tank.

And that's it. It's a straight run from the Dart pump to the assembly, and I'm expecting decent flow.