The Marineland 400g is level

by

, 11-21-2010 at 10:53 PM (3824 Views)

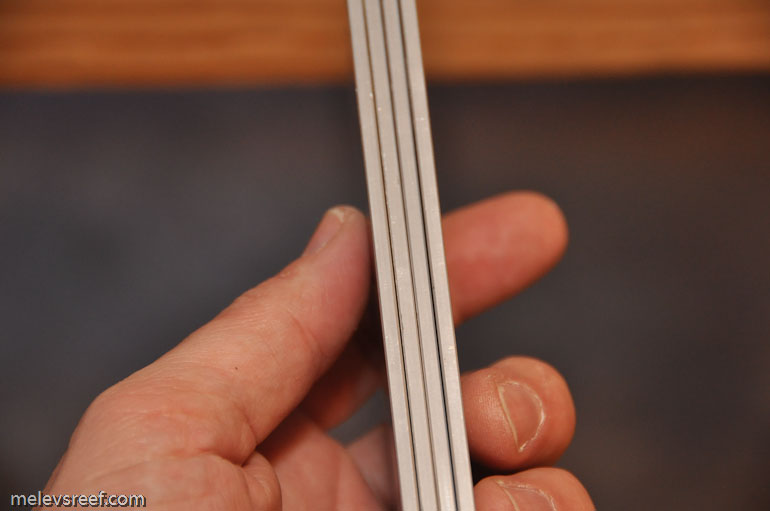

And like that, the tank is now level. I ran up to Home Depot and bought some 2" flat aluminum stock. An 8' stick was $17.50, and I cut it up into 6" sections with a jigsaw using a metal-cutting blade.

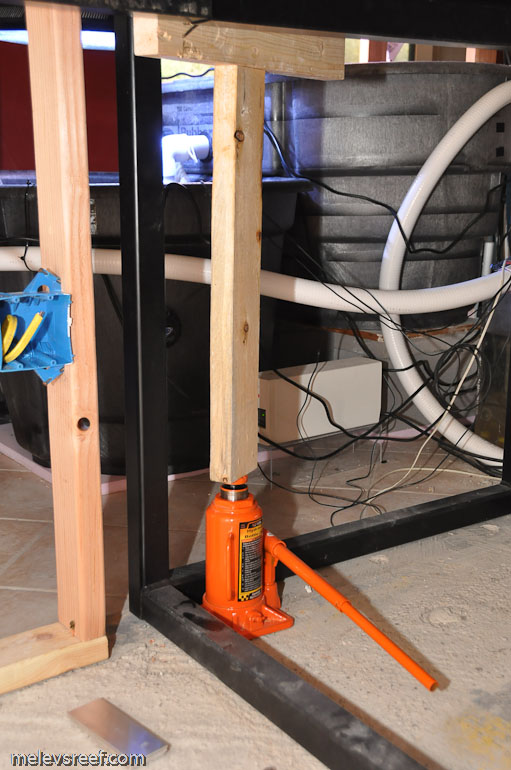

The aluminum is 1/8" thick. Using the can jack, I raised up the offending corner, slid the shims in place and lowered the stand back down on top of them.

I think I want to keep this Tank Boy around. He's really useful, and does wiring on demand.Oh, and by the way, to the right (his left) you can see the new framing where the wall was extended. The last circuit was wired in tonight: plugs for the lighting (MH & VHO).

I had an offer today to get some composite material to replace the aluminum, now that I know the thickness needed for each corner. So I may be replacing those before the water is added. I'd really like to fill that gap with more concrete, but don't know if it would do any good other than make me happy.